© Philadelphia Yearbook (1917)

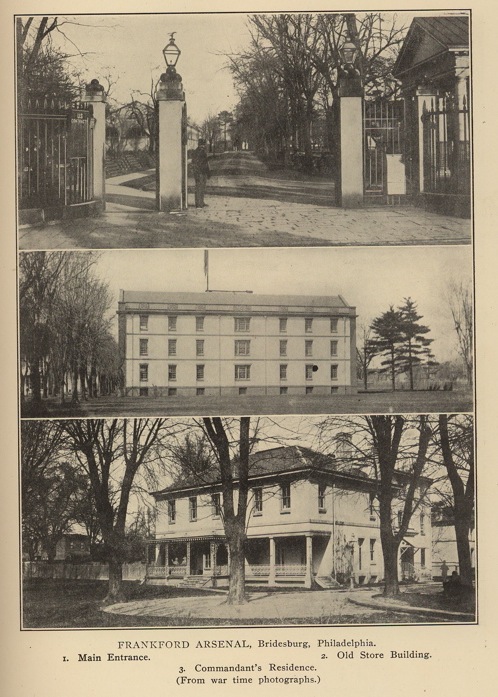

Frankford Arsenal, 1816

5301 Tacony Street, Philadelphia PA 19137

(main entrance from Bridge Street)

© Barbara M. Auwarter and

Joyce Halley, Workshop of the World (Oliver

Evans Press, 1990).

Frankford Arsenal

supplemented the Schuylkill Arsenal early in the

nineteenth century and continued in its function until

very recently. The Arsenal played an important role not

only in Philadelphia, but in the nation as well, serving

as the home of such important innovations as a variety of

early cartridge systems for breech-loading weapons, the

Maynard priming system, the Frankford friction primer,

and the recoilless rifle of World War II.

Activated in May, 1816, the Arsenal covered at that time

some 20 acres on Frankford Creek near its junction with

the Delaware River, sufficiently far from the more

densely populated sections of the city to be safe for the

storing of gunpowder. Within the tract, domestic quarters

and warehouse buildings were erected around an open

space, which was kept largely undeveloped over the entire

life of the complex, and was used as a parade ground.

While initially the primary role of the Arsenal had been

to serve as a storage depot and repair shop of military

weapons and ammunition, by the early 1840s it had assumed

a more prominent role in munitions development, starting

with the testing and proofing of various weapons and

gunpowder. Expansion to the east along Frankford Creek

toward the Delaware River was dictated by the rapid

subdivision of the dry land to the north and west into

city building lots to supply housing for an increasingly

industrialized community.

Major Philip V. Hagner was put in charge of the Arsenal

in 1851, and presided over the development of the first

steam-powered plant there, the purpose of which was to

manufacture percussion caps in a single operation. A

percussion cap factory was erected in the middle of a

tract adjoining the original tract to the east, which was

purchased in 1849. Hagner installed the inventor of the

cap machine, George Wright, as shop foreman; Wright's

machine was exhibited in 1854 at the Franklin Institute

and judged the best in the world.

Not only was ordnance manufactured on site, but also

machines to produce ordnance as well. By 1861, machinery

was being run day and night, as the Arsenal prepared for

war. After the outbreak of the Civil War, the Arsenal

manufactured percussion caps, paper fuses for detonating

explosives, and other munitions. Under Major T.T.S.

Laidley, and following an 1862 fire which destroyed much

of the Cap Factory, structural measures became a concern

that could limit damage in case of explosion; these

design ideas were incorporated in the range of buildings

known as the Laidley Laboratories. Captain Stephen

Vincent Benet became commanding officer in 1864, and

presided over the construction of the "ultimate

nineteenth century construction effort, a 'Rolling Mill'

to work copper and brass for caps and cartridges".

1

Designed in

industrial Italianate style by John Fraser, it was

completed in 1866, the year after the war ended. Because

of the drop in production after the war, the Rolling Mill

was used only for storage for twenty years.

2

With the lessening of the need for intense production,

scientific experimentation increased. In the 1890s, the

depot function was greatly reduced, and "the installation

concentrated on becoming the nation's center for powder

chemistry". 3

Testing was

conducted in the newly erected Proof House with an

associated 109-foot shooting gallery. Eventually the

proving of the smokeless powders being tested required

longer ranges than possible at the Arsenal, and this work

was moved to the Sandy Hook Proving Ground in New

Jersey.

In the first years of the twentieth century, and through

World War I, Frankford Arsenal produced mainly small arms

ammunition—a new cartridge factory facility was

installed in the old Rolling Mill. In 1940, Frankford

Arsenal was the only producer of military ammunition in

the United States. It took a leadership role in World War

II, not only producing but training employees of private

industries in the basics of mass production of military

ammunition. Possibly the most startling piece of research

and development to come out of its research laboratories

in this period was the recoilless rifle. At the end of

the war, ammunition production in private industry was

discontinued, and again Frankford Arsenal was the sole

producer of military ammunition in the United States.

As part of the planned reorganization of the Army, the

Arsenal's areas of responsibility were transferred to

other installations. In 1977, when Frankford Arsenal shut

down its production lines forever, the Arsenal covered

110 acres on which 246 buildings stood. Archaeological

investigations carried out in 1978 uncovered remains of

the original 1817 barracks (torn down in 1891) in the

middle of the parade ground. Today the "Arsenal Business

Center" is being rehabbed and the buildings occupied by

private companies.

1 John Milner Associates,

Inc., Historical and Archaeological Survey of Frankford

Arsenal, Philadelphia, PA, (manuscript, 1979), p. 33.

2 About 1,000 employees

were discharged; only Maynard's center-fire cartridges

continued to be made.

3 John Milner Associates,

Inc., p. 50.

Update May

2007 (by

Torben Jenk):

Renovations began in 1983 for

the "Arsenal Business Center" offering 2.4 million square

feet of "industrial/office/flex" space in over a hundred

different buildings on 86 acres. Spaces are available for

lease or purchase. Current tenants include Casani Candy

(wholesale confectioners), Profile Limo, Smith &

Soloman [Truck] Driver Training School and a catering

operation. Unusual tenants include two publicly

financed/privately managed "charter" schools, an opera

company and Hollywood productions. Franklin Towne Charter

School, started in 1999, has 978 high school students in

grades 9-12 with plans to serve students in K-8th grade.

Maritime Academy Charter School opened in 2003 and

teaches grades 5-12. These schools are clustered by the

gated entrance to the Arsenal and the students, in their

uniforms, evoke an earlier time at the Arsenal. The Opera

Company of Philadelphia uses a 14,000 square foot

building as their scene shop; in adjacent buildings they

store their inventory for twenty five full productions

(these sets are leased to other opera companies). Parts

of the movies Philadelphia, Twelve Monkeys and Fallen

have been filmed here.

See

also:

Historic American Engineering

Record, many items, search for

'Frankford Arsenal.'