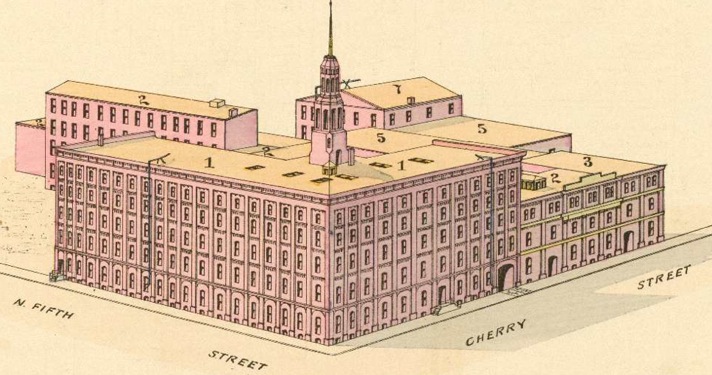

—Detail from Horstmann's Dress Trimmings, Military and Regalia Goods Manufactory, Hexamer # 2092-2093 (1887)

WILLIAM H. HORSTMANN & SONS, Manufacturers of Dress Trimmings and Military Goods.

5th & Cherry Streets, Philadelphia, PA.

This house was founded, in 1815, by William H. Horstmann, a native of Cassel, in Germany. He had learned the trade of silk-weaving in France, and, emigrating to the United States in the above-mentioned year, established himself in Philadelphia as a manufacturer of fringe, laces and trimmings of various kinds. He married the daughter of Frederick Hoeckly, a German settler in Philadelphia, and also a manufacturer of fringe, coach-lace and tassels. He devised several improvements in this trade, especially by introducing varieties in the styles and patterns of this class of goods, there being at that time only two patterns used in the trade, which were known as the Jefferson pattern and the Monroe pattern.

In 1824, he introduced into this country from Germany the use of plaiting or braiding machines, and about the same time he was the first to introduce into this country the use of the Jacquard loom, for weaving patterns in textile fabrics. His location was in the first instance at No. 50 North Third street, but within a short time he removed to a store next to the Harp and Crown tavern, afterwards known as the City hotel, and continued his business within a short distance of this point for many years.

In 1828, he commenced the manufacture of military trimmings as a special department, and this branch has grown to most important proportions, Horstmann's military goods being in demand throughout time country. The firm have also executed large Government contracts in this line for the War and Navy Departments. In 1831, he established a branch house in New York city, and about the same time erected a factory at the corner of Germantown road and Columbia avenue. The factory was continued here until time erection of the extensive building at Fifth and Cherry streets, where the works, salesrooms and offices of time firm now are. This massive structure is six stories high, and extends 140 feet on Fifth street and 200 on Cherry street, and reaches back to Race street. The separate departments into which the business is divided are thirty in number. More than 1000 distinct looms and machines are in use in the building, many of them very costly and some invented and used exclusively by this firm, the motive power being supplied by a steam engine of fifty horse power. The area covered by the works is about 11,000 square feet. Time number of hands employed is very large, about 500. When the erection of a vast factory at this point was first proposed, a strong opposition was made by time holders of the neighboring property. The ancient German Lutheran Church and burying ground, since removed, stood opposite the site, and a bill was introduced into the Legislature to forbid the use of a steam engine within 100 yards of any place of worship. The interests which such a bill would have affected injuriously, especially those of several newspapers, roused a strong opposition to it, and it failed to become a law. In 1845, William H. Horstmann, the founder of the house, retired from the business, and his two sons, William and Sigmund, assumed the management and it was under their direction that the new building, above described, was erected.

The goods produced by this house are of almost endless extent and variety. They include goods woven from all the various textile fibres—cotton, wool, silk, etc.—in every style, color and pattern, and are used for an infinite number of purposes. Narrow woven goods are time staple production, made up into material for dresses for both sexes, for use in daily life, and for regalia for "societies;" for the costumes of the stage, the upholstering of houses and of carriages, the uniforms of soldiers, together with equipments for the same, and for funeral purposes. The raw material used in the manufacture is to a great extent very costly, and their store rooms often hold as much as $200,000 worth of goods in an unworked state. There are two rooms devoted to power looms in the factory, one for coach lace and one for other styles of weaving, in which about 250 of these machines are constantly running. The braiding machines in the coach lace room are very noteworthy. The cord to be covered with braid is drawn through an opening in time middle of a flat, circular, metallic plate, about 15 inches across. Up to a point on this cord, about a foot above the plate, the threads of the braiding material converge, like the ribs of a tent-roof, and there weave in and out and out and in, as the coating of braid grows, and time covered cord rises and is wound away above. The weaving is accomplished by the motion of the spools below that carry the different threads of the braid. These spools stand in uprights, which are carried round and amongst each other in curved slots in the above-mentioned broad metallic plate. All but two of these spools run in and out among each other, with a swift, easy and intricate motion, mind so rapid that time eye can hardly follow it, while one or two special spools run steadily round and round among time twisting spools with the most extreme swiftness. Many other machines, displaying equally ingenious mechanism, are used in the factory. The various details of equipment manufactured and supplied by this house are also important, both for their number and the superior quality of the manufacture.

The one article of swords may be taken as an instance. This trade grew naturally and immediately out of the established army and navy goods department of the works, it being necessary that the sword itself should be furnished together with the sword-belt and other trappings all complete. Every part of the sword and trappings, with the exception of the blade, is made on the premises. The blades are almost all imported from the ancient German sword-blade emporium of Solingen, where, it is said, swords have been made ever since the year 1147, when Count Adolphus of Berg brought home from the East and established there the business of forging Damascus blades. There is in this department a stock of some thousands of blades, of many different patterns and sizes, ready to be set and finished. Any style or sword can be had from this warehouse, from the plainest kind up to a presentation sword worth a thousand dollars. In addition to their own vast capacity for manufacturing goods, this firm also import and sell large quantities of goods manufactured elsewhere. The house has also two stores in New York and an agency in Paris. The brothers, Sigmund and William Horstmann, the successors of the founder, died within two years of each other, the former in 1870 and the latter in 1872. The business is continued under the same name, and no material changes have taken place. The house is recognized as the leading establishment in their special line in the United States.

—Charles Robson, Manufactories & Manufacturers of Pennsylvania (Galaxy, 1875), pp. 406-8.

Update:

This site is now occupied by the U.S. Mint.

See also:

Horstmann's Dress Trimmings, Military & Regalia Goods Manufactory, Hexamer # 9 (c. 1866)

Horstmann's Dress Trimmings, Military & Regalia Goods Manufactory, Hexamer # 81 (1866)

Horstmann's Dress Trimmings, Military and Regalia Goods Manufactory, Hexamer # 626-627 (1872)

Horstmann's Dress Trimmings, Military and Regalia Goods Manufactory, Hexamer # 2092-2093 (1887)