U.S. Gypsum, 1929-1991, demolished 2007.

South of 56th Street, west of the Schuylkill River to Eastwick Avenue, Philadelphia PA

Compiled by Sean McDonnell,

Oct. 2007.

The 1920s was a period of

rapid growth for the United States Gypsum Company, who

constructed several new facilities throughout the

country.[1] In 1929, they began building a plant in

southwest Philadelphia on land formerly owned by the Gulf

Oil Company.

Bordered on the north by 56th St, the south by Gulf Oil,

and the west by the Philadelphia and Reading Railway

(which provided rail service), the plant appeared to rely

on the Schuylkill River for delivery of inbound raw

materials. The plant was originally configured to produce

Sheetrock, the company’s name for gypsum wallboard,

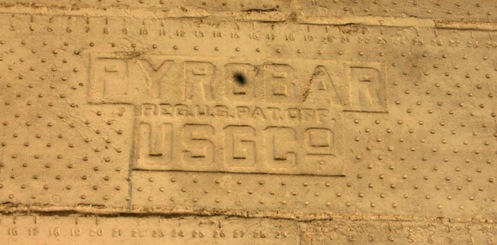

and gypsum block, known as Pyrobar. The company’s

own Pyrobar could actually be found throughout the plant.

Photo of a Pyrobar

block, part of a wall in a room near the west end of

the calcining mill building. Though due to the age

of this particular structure, it is unlikely this

particular block was produced at the

plant.

Gypsum, chemically known as calcium sulfate, is a

naturally-occurring mineral. It is such a versatile

substance because it can be ground into powder , molded

into the desired shape, and be returned to its original

rock-like hardness simply by adding water. The gypsum is

first calcined to drive off water molecules that are part

of the compound, forming plaster. This plaster is mixed

with water and additives to form slurry. This slurry is

sandwiched between sheets of heavy paper to form the

gypsum board, which is then cut to the proper shape,

dried in a heater and prepared for shipping.[2]

It was a fine example of form following function in

industrial architecture and design, with varying

rooflines throughout the building to accommodate the

different production lines. The plant most likely got by

producing Pyrobar, and regular plaster, as a site plan

from the Factory Mutual Fire Insurance Company shows

portions of the plant were devoted to bagging and storage

of empty bags. The market for gypsum board did not

explode until World War II, when the need for a fast,

reliable building material finally allowed Sheetrock to

surpass plaster-on-lath as the preferred method for

finishing home interiors.[3]

View northward

from the west bank of the Schuyklill, showing the bridge

that ran from the gypsum storage building to the

calcining mills. The green pipes extending towards the

waterfront were likely a pneumatic materials handling

system for unloading raw gypsum from ships or

barges.

The sheetrock business definitely grew for the plant, as

the fire insurance map shows additional manufacturing and

storage space for gypsum board was added to the plant in

1951, and again in 1960. By the time the fire insurance

survey was completed in 1980 by, the buildings housing

the gypsum block production lines had been demolished,

and went on to serve as the site for raw materials

storage. Between 1986 and 1991, US Gypsum sold the plant

to a company called Certified Concrete. Plant records

showed little activity dated after 1993, so that is

likely the year the plant closed for good. The facility

loomed silently on the west bank of the Schuylkill,

serving as shelter for squatters and as a playground for

urban explorers and photographers, until June of 2007

when it was leveled.

Aerial view, looking

north. The large corrugated-metal structure at the

center-right was originally storage for raw gypsum.

The long, two-story structure to the south was the

gypsum board production area. The structures to the

south of the gypsum board building housed kilns and

calcining mills to convert gypsum to its usable

form. This location allowed the processed plaster to

be delivered to the board production area, or to the

block production buildings, the concrete floors of

which are visible at the bottom of the

picture.

View looking southeast,

up at the gypsum storage building. The concrete

silos were roughly 4 stories tall, with the

remaining vertical space in the building occupied by

a large gantry crane with clamshell bucket to feed

the conveyor and auger.

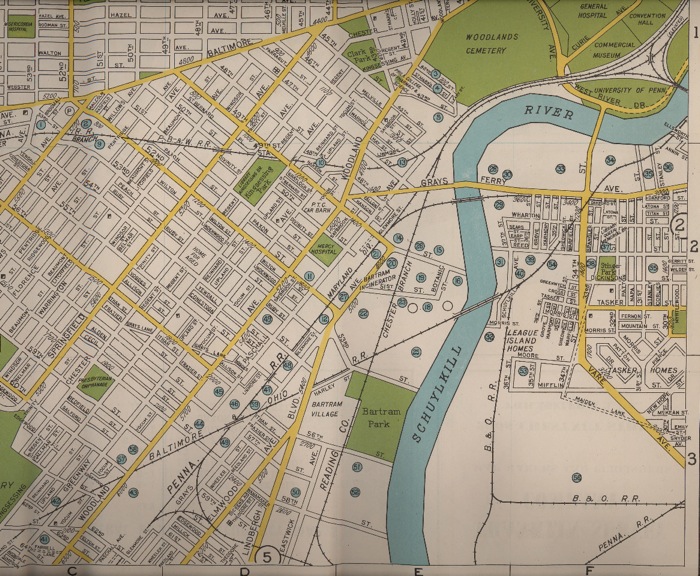

U.S. Gypsum is

#51, just below "Bartram Park", west of "Schuylkill."

Franklin's Street & Business Occupancy Atlas of

Philadelphia & Suburbs, 1946, detail Map No.

6.

FOOTNOTES:

1. History & Innovations of the United

States Gypsum Co.

2. Drywall - How It Is

Made.

3. Drywall - From 1916 to

today.

ALSO:

Audio-visual history of gypsum and gypsum

products.

USG Corporation website.