Bridesburg Manufacturing Co.

[East side of Richmond Street between Franklin & Locust, Philadelphia PA]

—© Edwin T. Freedley,

Philadelphia

and its Manufactures (1867), pp. 351-351 &

587-592.

"These works, of which we

have already given the incidents connected with their

establishment and early history, are located at

Bridesburg, a flourishing town now constituting a part of

the city of Philadelphia. They are built in the form of a

bollow square, cover an area of one hundred and sixty

thousand square feet, and consist of a Foundry one

hundred and thirty by fifty feet; a Blacksmith shop, one

hundred and twenty by fifty feet, having eighteen forges

and four trip-hammers, for making, in addition to other

things, Bolts-of which seven hundred are made and used in

the machinery work daily; a buildidg one hundred and

ninety by thirty-two feet, containing an apartment used

as a Brass Foundry, and also for "cleaning" the castings

after they have been subjected to the process of

"pickling," and a well-adapted room for storing patterns

when not in use. The Machine Shop is a building two

hundred and twenty-five by thirty-eight feet, and the

large structure formerly used as an armory, occupying the

entire southern front, is now fitted up exclusively for

making Ring Spinning Frames, and one frame of two hundred

and four spindles is turned out daily. A capacious

Elevator is employed for raising and lowering castings

and other objects between the different stories of the

Machine Shop; and a Railway connects this and the

Foundry. The Carpenter Shop is a building one hundred and

sixty-eight by thirty feet, three stories high; and each

of the various rooms and departments is supplied with

tools and machinery of the most perfect construction,

peculiarly adapted to the purposes for which they are

designed. In the Wood-working Room are two of Daniel's

Planing Machines, and one of Woodworth's, and Moulding

and Sawing Machines capable of facilitating and making

more perfect the woodwork required for the Carding

Engines, Looms, etc. All the wood used is kept for the

space of two years before being shaped by the machinery,

so as to properly season it, and after it has been thus

seasoned and brought to the form desired, it is placed in

a commodious Drying-bouse, entirely fire-proof, and

always kept by the heat of steam at a temperature of

seventy-five degrees, for the purpose of being still more

thoroughly seasoned. The tools and Machinery for

performing the work in the several shops are mostly made

by their own workmen; among which may be classed several

Drills of new and improved construction, Boring Mills,

and other self-acting machines, of the most beautiful

design and perfect workmanship.

"To attempt a recital of the various useful and novel

Machines made in these Works, the most important of their

class in the United States, would transcend our limits.

We shall advert to only a few of the most important which

are peculiar to the establishment, or which have received

the benefit of the improvements of Mr. BARTON H. JENKS,

who is one of the most ingenious of American inventors.

"1. LOOMS

Of Looms a large number of different styles are

manufactured at these works, ranging from the single

Shuttle, or ordinary Loom, through the more intricate

forms of two Shuttle Looms for weaving Checks; three, and

four Shuttle Looms, for weaving Ginghams and other

fabrics requiring a corresponding number of colors in the

weft, to the more enlarged Carpet Loom; and all of these

embrace, in a greater or less degree, improvements and

advantages not possessed by Looms manufactured elsewhere.

The several improvements in the Looms are covered by

seven distinct patents; and the main features

accomplished by these inventions, so far as they relate

to the two, three, and four Shuttle Looms, may be said to

consist in the expeditious manner of moving the Shuttle

Boxes to change the picks of weft; and, by certain new

constructions, combinations, and arrangements of parts

essential to this operation, and to others of an

important character, by which as many picks of weft can

be made by these two, three, and four Shuttle Looms, as

by the single Shuttle Loom. As an exemplification of

this, it may be stated, that so perfect is the

arrangement of the various parts of this latter

description of Looms, and the principle upon which they

work, that they make one hundred and thirty picks of weft

per minute, whereas the same class of ordinary Looms only

make one hundred and ten. The Muslin Loom will run one

hundred and sixty picks per minute, and produce nine

pounds of muslin a yard wide, sixty-four picks to the

inch, per day.

"2. JENKS' COTTON SPREADER.

Is made entirely of metal, thus insuring greater

steadiness and durability. The beater, shafts, blades,

and feed-rollers, are made of cast-steel; the shafts

which drive the feed are braced together in such a manner

that the teeth in the diagonal shaft cannot break; and,

by an ingenious application of the elastic principle of

air, the Machine is constructed to make the lap of

uniform thickness, and of such compactness that any

portion of it will sustain its own weight. More-over, the

whole machine works without producing any dust in the

room.

"The product of the Jenks "Spreader" is as follows: The

gallows-shaft having four hundred and fifty revolutions,

and the beaters eighteen hundred, produce per day two

thousand four hundred and ninety-six yards. Doubled on

the same machine three times, the produce will be

thirty-eight laps, each twedty-two yards long, weighing

each eighteen pounds total weight, six hundred and

eighty-four pounds. If two machines are used, the produce

will be one hundred and thirteen and a half laps per day,

each twenty-two yards long, weighing eighteen pounds in

total weight, two thousand one hundred and two pounds.

"JENKS' PICKER, as well as the Spreader, has an

established reputation for excellence, especially in

stopping action at the right point, without making the

Cotton "bally and ropy." The product of this Picker is

three thousand pounds per day when driven at the speed of

twelve hundred revolutions a minute.

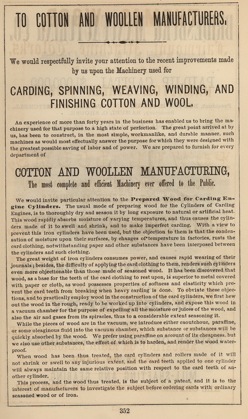

"3. THE CARDING ENGINES.

The self-stripping Cotton and Woolen Carding Engines,

manufactured at these Works, are different from the

Carding Machines generally used. In ordinary machines it

is necessary to stop every thirty minutes, and with the

laborious use of band-cards clean out the secreted

Cotton, so as to leave the teeth projecting. Jenks'

Carding Engines are provided with a mechanism called a "

Self stripper," which constantly picks out the Cotton

from the bottom of the teeth, returns it to the Cylinder,

and drops it on the points of the teeth, where the combs

catch it and pass it out into a can.

"One of Mr. Jenks' improvements which have given his

Carding Machines the preference of the market, both in

this country and in England, is his method of preparing

the wood, of which the cylinders are made. The usual

method of preparing it is to dry and season it by long

exposure to natural or artificial heat. Wood so seasoned

inevitably absorbs moisture of varying temperatures, and

the cylinders of which it is made will alternately swell

and shrink, and thus make imperfect carding. To prevent

this, iron cvlinders have been used, but there are also

serious objections to their use. Mr. Jenks' plan is to

hew out the wood in the rough, ready to be worked up into

Cylinders, and then expose it in a vacuum chamber to

extract all the moisture and juices, and also all the air

and gases from its spiracles. This he accomplishes

thoroughly; then, while the wood is in the vacuum, he

introduces caoutchoue, paraffine, or some oleaginous

fluid, which the pieces quickly and fully absorb, and the

effect is to render the wood completely moisture-proof

and water-proof. His Card-Cylinders and Rollers, made of

wood thus treated, will not shrink or swell, and the

card-teeth applied to one Cylinder will always maintain

the same relative position with respect to the card-teeth

of another Cylinder.

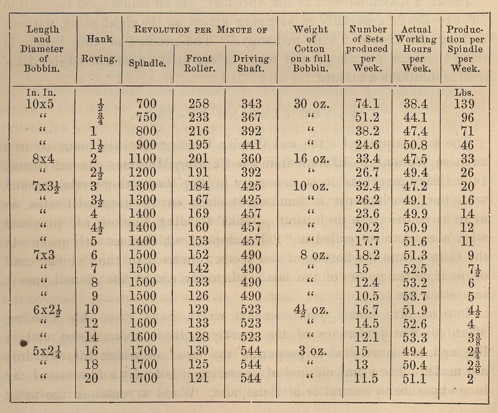

"4. JENKS' FLY FRAME.

Is well known, and used in all factories, having the most

approved machinery. The productiveness of this admirable

Machine is given in the following Table:

"5. THE JENKS' PATENT SPINNING FRAMES.

Have the reputation of being the best in the United

States, and on the most approved system. These machines

are made with different numbers of spindles, the usual

size being a machine of two hundred and four spindles.

Each spindle will produce six skeins of number twenty

yarn, each skein weighing one-twentieth of a pound-all

weighing six-twentieths of a pound; velocity of the

spindle seven thousand turns per n-iinute, with wooden

bobbin. The spindles have a self-lubricating bolster,

which will run a month on six drops of oil. An important

coneing motion forms the bobbins with taper ends, using

paper cones on the spindles, and effecting thereby a

great saving of weight, and consequently of power in

carrying the wooden bobbins ordinarily in use. The reel

is an important machine in a Cotton Factory where the

yarn is spun to be sold in the market, and much attention

has been bestowed upon this machine by the Bridesburg

Manufacturing Company. The reel marks the skeins by an

automatic motion, and when seven skeins are marked off at

each spindle, the driving-belt is thrown off and the

machine stops. By another ingenious arrangement the

skeins are removable from the shaft of the reel without

lifting the reel, (which is the case in all the reels

excepting those made by this Company), thus enabling

smaller girls to operate the Machine.

"6. JENKS' IMPROVED CYLINDER COTTON GIN.

Is, novel for the peculiarity of the construction of the

cylinder, which operates in combination with a stationary

straight-edge and a spirally- grooved roller called "the

agitator." The straight-edge is fixed in a position

parallel with, and tangential to the cylinder, with its

thinner edge almost in contact with the upper side of the

same and the agitator, so as to rotate rapidly at a short

distance above and parallel with the straight-edge. The

periphery of the cylinder consists of numerous steel-wire

teeth imbedded in Babbitt metal, in positions inclined in

the direction of the cylinder's motion, so that after the

cylinder is "ground" or finished, each tooth presents a

separate, sharp, and smooth point, tangential to the

cylinder surface. When in operation, the cotton and seeds

are carried by the cylinder against the straight-edge,

where they are rolled over and over by the agitator,

until the teeth of the cylinder have stripped off the

fibre, the seeds immediately drop down, through a

grating, into a receiving box. The fibre is at the same

time being continually removed from the cylinder in the

usual manner, by a rotating brush behind the

straight-edge. The teeth of the cylinder are made of the

finest steel needle wire, rolled into a double razor-edge

section, and secured obliquely around the cylinder, with

their sharper edges in directions transverse to the axis

of the same ; consequently, after the cylinder is "ground

off" in finishing, it presents a serrulated surface, or a

surface studded over with innumerable sharp and smooth

tangential teeth, admirably adapted both for entering and

leaving the fibres.

"It will gin any Cotton, however trashy it may be, and

take nothing through but the lint; it neither cuts nor

naps the fibres in the least, leaving them nearly as long

as when separated by band; whilst it will clean as great

a quantity in the same time as any other Gin occupying

the same extent of space, and run as easy. It will also

last as long, if not longer, than the Saw-gin, and cost

no more for repairs.

"Besides these special machines, it may safely be said

that all of the machinery made at these Works is much

lighter, neater, and of better iron, easier to manage,

cheaper to run, and will turn off more work of equal

excellence than any English machinery ever built. Since

the close of the war, and since Cotton-manufacturing has

returned to its normal profits, mill-owners have

commenced to throw out English cards, drawing frames,

slubbers,. and speeders which they bad been persuaded or

forced to buy, and are substituting American in their

place. The whole range of English machinery is heavy and

requires great power. Their cotton machinery, unimproved

by the adoption of American inventions, is clumsy and

weighty to the degree that might be expected in a are at

their minimum value. Besides, many American improvements,

for country where steam and human labor cost but little,

and iron and coal which patents have been taken out in

England, are inaccessible to the British machine

manufacturers.

"The BRIDESBURG MANUFACTURING COMPANY has a paid-up

capital of one million of dollars, and employs five

hundred hands. The principal officers are BARTON H.

JENKS, President; JOSEPH G. MITCHELL, formerly cashier of

the Mechanics' Bank, in Philadelphia, Treasurer; SAMUEL

O. SHOUSE, Secretary. The office in Philadelphia is at 65

North Front street."

Resources:

"Bridesburg Manufacturing Co., 25th Ward,

Philadelphia, Pa.," (1866), Hexamer

#75.

"Bridesburg Manufacturing Compy.,

Bridesburg, 25th Ward, Philadelphia," (?), Hexamer

#440-441.

"Bridesburg Machine Works, Wm. F. McGill,

Bridesburg, 25th Ward, Philadelphia, Pa.," (1891),

Hexamer #2501-2502.